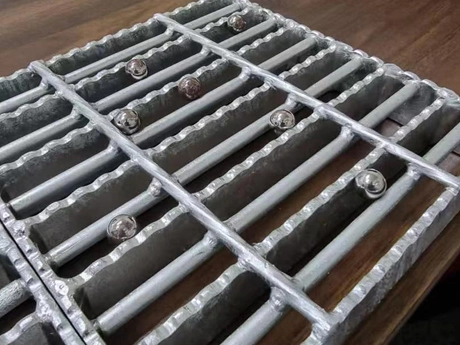

Rejilla a prueba de bolas

Ball-proof gratings are open-mesh gratings designed to prevent objects from falling through the gaps between load-bearing bars. Typically, they are engineered to block the passage of 35mm or 20mm spheres/balls. These gratings feature a smaller clear hole spacing. Commonly used in offshore environments, ball-proof gratings effectively prevent objects from falling onto people or items below the grating platform above.

Where Do You Need Ball Proof Grating?

Any risky walkway platform, where there are pedestrians or equipment that prevents installation.

-

Offshore platform

-

Equipment maintenance walkway and platform

-

Maintenance platform

-

Chemical platform, etc.

According to the manufacturing process, it can be divided into small spacing grating and round bar added grating.The small mesh spacing grating controls the minimum bearing bar spacing to 35mm and 20mm or smaller to ensure that objects do not fall under the grating.

Add round bar ball proof grating. Generally, the grating with 30mm bearing bar spacing is added with 6mm or 8mm round steel in the middle to ensure that the 15mm small balls do not fall. Compared with directly making small spacing gratings, this method is more economical, so it is widely used in the marine and offshore area.

Regular Ball Proof Grating Specification

| Model | Specification | Grating | Round bar | Type | Treatment |

| BPG1 | D6(W255/30/100SG) | W255/30/100SG | Ø6 | Round bar ball proof grating | HDG&Mill Finished |

| BPG2 | D8(W255/30/100SG) | W255/30/100SG | Ø8 | Round bar ball proof grating | HDG&Mill Finished |

| BPG3 | D6(W325/30/100SG) | W325/30/100SG | Ø6 | Round bar ball proof grating | HDG&Mill Finished |

| BPG4 | D8(W325/30/100SG) | W325/30/100SG | Ø8 | Round bar ball proof grating | HDG&Mill Finished |

| BPG5 | W255/20/100SG | W255/20/100SG | Small mesh ball proof grating | HDG&Mill Finished | |

| BPG6 | W325/20/100SG | W325/20/100SG | Small mesh ball proof grating | HDG&Mill Finished |

Features of Painted Steel Grating

-

Strong aesthetics

Red, yellow, blue, white, green and other colors can be selected according to needs.

-

Lower cost

Compared with surface treatment methods such as hot-dip galvanizing, the processing cost of painted steel grating is lower.

-

Medium anti-corrosion

It has a certain anti-rust ability and can resist corrosion of steel from the external environment to a certain extent.

-

Diverse performance

It has ventilation, lighting, heat dissipation, explosion-proof, anti-slip and other properties, and can effectively prevent dirt accumulation.

-

Good load-bearing capacity

Made of high-quality steel, negative flat steel and twist steel are reasonably arranged and welded, with high load-bearing capacity